In recent years,

corn starch industry has maintained steady growth rate and corn starch processing technology has matured and stabilized. However, protein dewatering

process and equipment used tend to vary from case to case.

In corn wet

milling process, after extraction of germ and fiber, centrifugal separators are

normally used for separation of gluten from starch, yielding thin gluten liquid

of 15-25g/l density. This in turn is thickened by gluten thickener (GT) to

obtain thick gluten liquid of 80~110g/l density. Thick gluten liquid needs to

be further dewatered and dried to yield final commercial gluten powder.

Currently, the rotary vacuum filter (RVF) and plate and frame filter

press are widely used for this application. Another alternative, tried by some

processers, is the decanter centrifuge. The following part of this paper is a brief

comparison between these common protein dewatering methods and related

equipment.

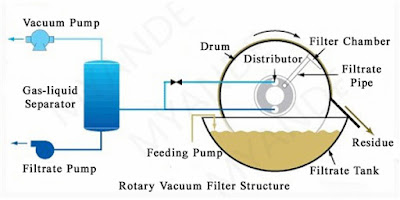

RVF

currently represents the mainstream gluten dewatering equipment for maximum

separation of insoluble gluten from water.

|

| Rotary Vacuum Filter Structure |

This process is preferable for the

features below:

● Long-time

continuous operation mode.

● High

automation level leading to simplified operation procedure, reduced human

interference in the operation process, and reduced labor cost requirement.

● Clean

production environment as the complete dewatering process takes place inside

the enclosed equipment chamber.

Nevertheless,

the RVF is not free from disadvantages. Moisture content of the discharged material

moisture is relatively higher at 58%~60% and power consumption is comparatively

higher.

2. Plate

and Frame Filter Press

The

plate and frame filter press came into use earlier than rotary vacuum filter

and is currently still used in some starch factory for gluten dewatering

process.

The most

obvious advantages of plate and frame filter press is the relatively lower

moisture content in the discharged material at 50%~55% and lower power

consumption.

|

| Plate and Frame Filter Press |

The negative

side of plate and frame filter press is:

● Incapable

of continuous operation as it relies on pressure, which needs to be maintained

for some time, to remove water from protein. The solution is to use multiple

units in parallel.

● Intense

work load for the operator for moving plates apart and cleaning the cloth.

Although mechanical plate parting devices have been tried, human interference

in this process is still required.

● Undesirable

working environment due to scattering of protein particles on the operation

platform.

About 10 years

ago, some corn starch processors started experiment with decanters with little

success. In recently years, with the progress of technology, decanters are

again used for protein dewatering.

|

| Decanter Centrifuge Structure |

The decanter

centrifuge has the following advantages:

● Smaller

operation space requirement than RVF and plate & frame filter.

● Capability

of continuous operation.

● High

level of automation and lower labor intensity.

● Clean

and hygienic operation without pollution caused by scattering of protein and

acid gas.

On

the other hand, decanter dewatering application requires addition of chemicals

into the thick gluten liquid. There is so far little sure evidence for its

watering effect even though some manufacturers assure that the moisture content

of the discharged material will be at 55~58%.

Conclusion: From the above

comparison, it can be concluded that each of these three methods has pros and

cons. The choice depends on comprehensive consideration of various factors that

include availability of workshop space, initial investment, cost of steam,

electricity and labor, cost of consumables, operation environment, and

user-friendliness. Currently, most corn starch processors in China opt for RVF

for this application.

没有评论:

发表评论